Food-grade silicone hose: the perfect combination of safety and efficiency

In modern food, beverage, pharmaceutical and other industries, the transportation and handling of materials are crucial to the quality and safety of products. As a key component, food-grade silicone hose stands out with its unique advantages and becomes the first choice of many companies.

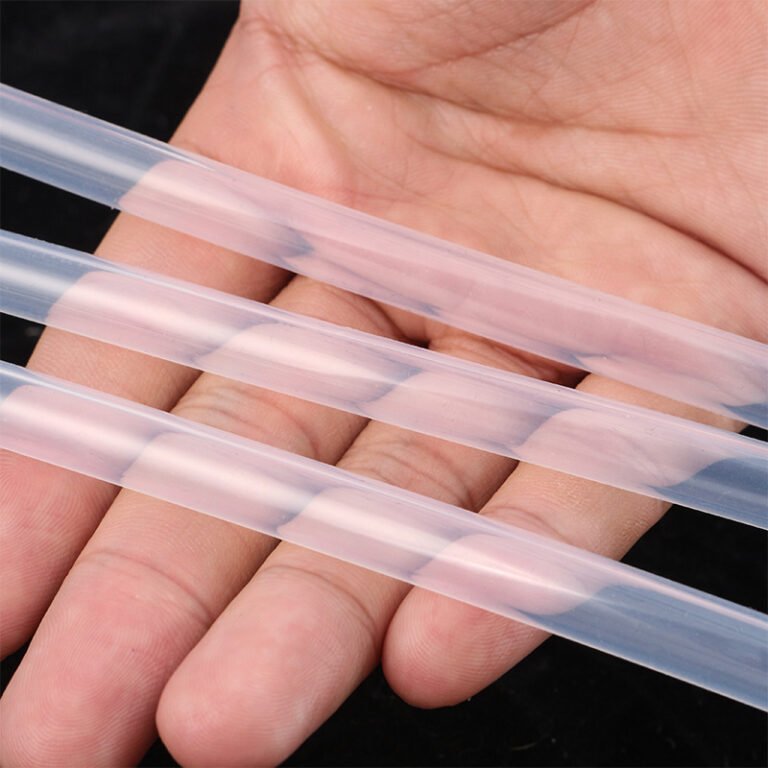

The most notable feature of food-grade silicone hose is its excellent safety. It is made of high-quality silicone material, non-toxic, tasteless, and odorless, and meets strict food safety standards, such as FDA (US Food and Drug Administration) and LFGB (German Food and Daily Necessities Law) certification requirements. This means that during the transportation of food and beverages, the silicone hose will not release any harmful chemicals into the material, ensuring the purity and safety of the product, so that consumers can eat it with confidence.

In terms of hygiene, silicone hose has excellent performance. Its surface is smooth, not easy to breed bacteria and microorganisms, and easy to clean and disinfect. Whether it is soaked in chemical disinfectants or sterilized with high-temperature steam, the silicone hose can maintain good stability without deformation, aging or damage, thereby effectively preventing cross-contamination and ensuring the hygiene and cleanliness of the production process.

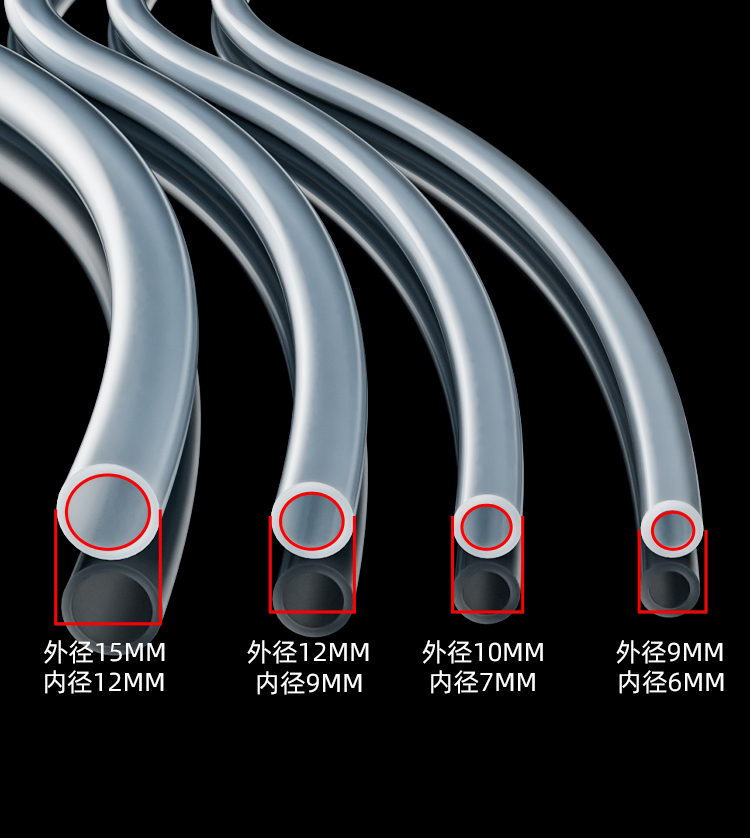

The physical properties of food-grade silicone hose are also excellent. It has good flexibility and elasticity, can bend and stretch easily, and adapt to various complex pipeline layouts and installation environments. This flexibility not only facilitates operation, but also reduces the risk of pipeline rupture caused by bending, and improves the reliability and stability of the conveying system. At the same time, the silicone hose also has a high pressure resistance and can withstand a certain pressure to ensure that the material flows smoothly in the pipeline without leakage or blockage.

Temperature resistance is also a highlight. The silicone hose can work normally in a wide temperature range and can generally withstand temperature changes from low-temperature freezing to high-temperature cooking. In the food processing process, whether it is the transportation of refrigerated and fresh-keeping materials or the filling of products after high-temperature sterilization, the silicone hose can consistently maintain good performance, and its physical and chemical properties will not be affected by temperature fluctuations, which provides a strong guarantee for the continuity and stability of the production process.

In addition, the food-grade silicone hose also has good chemical corrosion resistance, can resist the erosion of a variety of acid and alkali solutions and organic solvents, and is suitable for conveying various food and beverage raw materials of different properties, further expanding its application range.

To sum up, food-grade silicone hose has become an indispensable and important part of the food, beverage, pharmaceutical and other industries due to its high safety, hygiene and easy cleaning, excellent physical properties, good temperature resistance and chemical corrosion resistance. It plays a key role in ensuring product quality and production efficiency, helping companies stand out in market competition and bringing consumers better quality and safer products.