Silicone hose: a versatile tubing with excellent performance

Silicone hoses are widely used in many fields such as modern industry, medical treatment, and food. They have become an indispensable material with their unique performance advantages.

1. Material properties of silicone hoses

Silicone is a highly active adsorption material with stable chemical properties. Silicone hoses are made of silicone and have good heat resistance. They can be used in a wide temperature range and can generally withstand temperatures from -60°C to 200°C, which allows them to work normally in industrial transmission under high temperature environments and special experimental environments at low temperatures. Moreover, silicone has excellent aging resistance, and it is not easy to age or crack after long-term use, which ensures the service life of the hose.

2. Physical performance advantages

Good flexibility

Silicone hoses are soft and elastic, easy to bend and shape. In complex pipeline laying environments, it can easily adapt to changes in various shapes and angles, will not be damaged by bending, and is convenient for installation and use. This flexibility also makes it perform well in the connection of some equipment that needs to be moved or vibrated frequently.

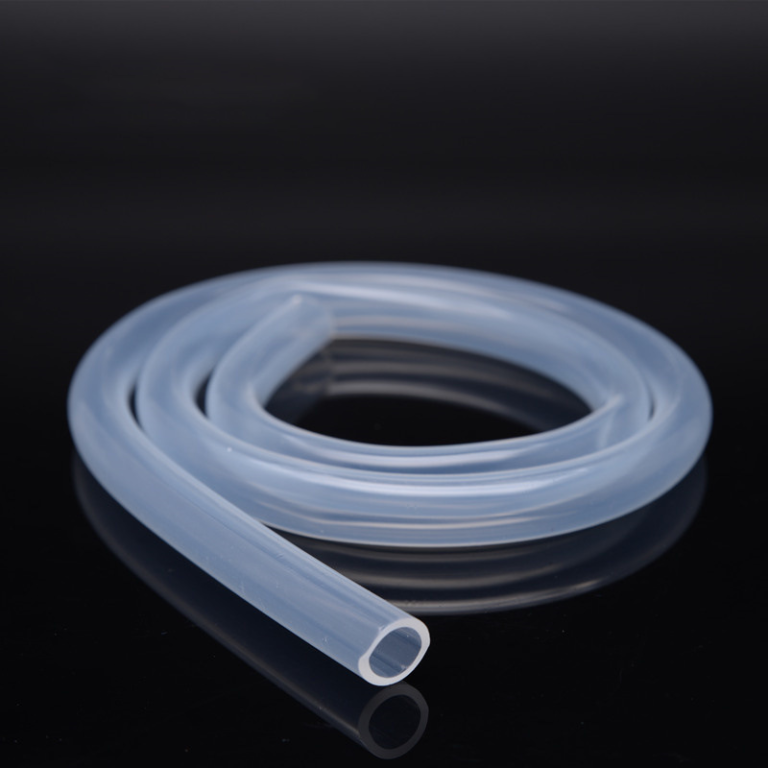

High transparency (some silicone hoses)

Some silicone hoses have high transparency, which is particularly important in the medical and food industries. In applications such as medical infusion, medical staff can observe the flow of liquids through transparent silicone hoses. When delivering food and beverages, it is also convenient to check the state of the material in the tube.

3. Chemical stability and corrosion resistance

Silicone hoses have good tolerance to many chemicals. It can resist the erosion of most corrosive substances such as acids, alkalis, organic solvents, etc. In chemical production, when corrosive liquids or gases need to be transported, silicone hoses can effectively prevent pipelines from being corroded, ensure the safety and stability of the transmission process, and reduce safety hazards such as leakage.

4. Wide range of application areas

Medical field

In medical equipment, silicone hoses are widely used for infusion, blood transfusion, drainage and other operations. It has good biocompatibility, will not cause adverse reactions to the human body, and can meet the strict requirements of hygiene, safety and precise delivery in the medical environment. For example, in some delicate surgical instrument connections, silicone hoses can accurately transmit liquids or gases to assist the smooth progress of surgery.

Food industry

Food-grade silicone hoses are an important part of the food processing and beverage production process. It can be used to transport various foods and beverages such as milk, juice, and alcohol, and meets food safety and hygiene standards. Because it does not react chemically with food, it will not contaminate food, ensuring the quality and safety of food.

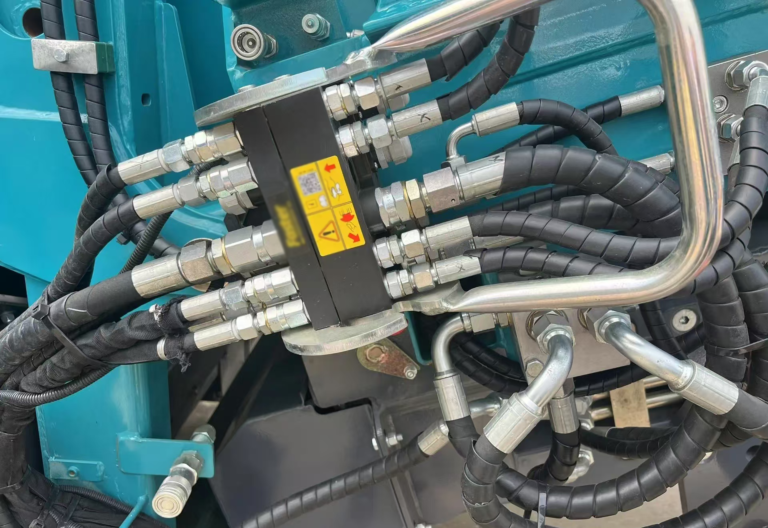

Industrial field

In industrial production, silicone hoses are used to transport various liquids, gases, powders and other materials. For example, coolant delivery in automobile manufacturing, gas delivery in the electronics industry, and material transmission in chemical production. Its high temperature resistance and corrosion resistance enable it to adapt to complex and harsh industrial environments.

V. Processing technology of silicone hoses

The processing of silicone hoses usually includes main processes such as mixing and extrusion. During the mixing process, the silicone raw materials are fully mixed with various additives (such as vulcanizers, etc.) to improve their performance. The extrusion process is to extrude the mixed silicone material into a hose shape through a specific mold, and after extrusion, subsequent treatments such as vulcanization are required to further improve the strength and stability of the hose.

VI. Market prospects and development trends

With the continuous development of science and technology and the improvement of material performance requirements in various industries, the market prospects of silicone hoses are very broad. In the medical field, the demand for more sophisticated and safer silicone hoses continues to increase; in the food industry, the improvement of food safety and hygiene standards has also prompted the continuous improvement of food-grade silicone hoses. At the same time, in emerging fields such as industrial automation and new energy, silicone hoses are also expected to find more application scenarios and develop in the direction of high performance, multi-function and environmental protection.