Pressure testing steps for rubber hoses

一、 Preparation work

1. Determine testing standards

Firstly, you need to clarify the pressure testing standards applicable to rubber hoses. Different types of rubber hoses may have different testing requirements, such as national standards, industry standards, or specific product standards.

Understand the pressure range, testing methods, and qualification criteria in the testing standards.

2. Select testing equipment

Select appropriate pressure testing equipment according to the requirements of the testing standards. Common pressure testing equipment includes manual pressure testing pumps, electric pressure testing pumps, pressure sensors, etc.

Ensure that the accuracy and range of the testing equipment meet the testing requirements, and perform calibration and inspection before use.

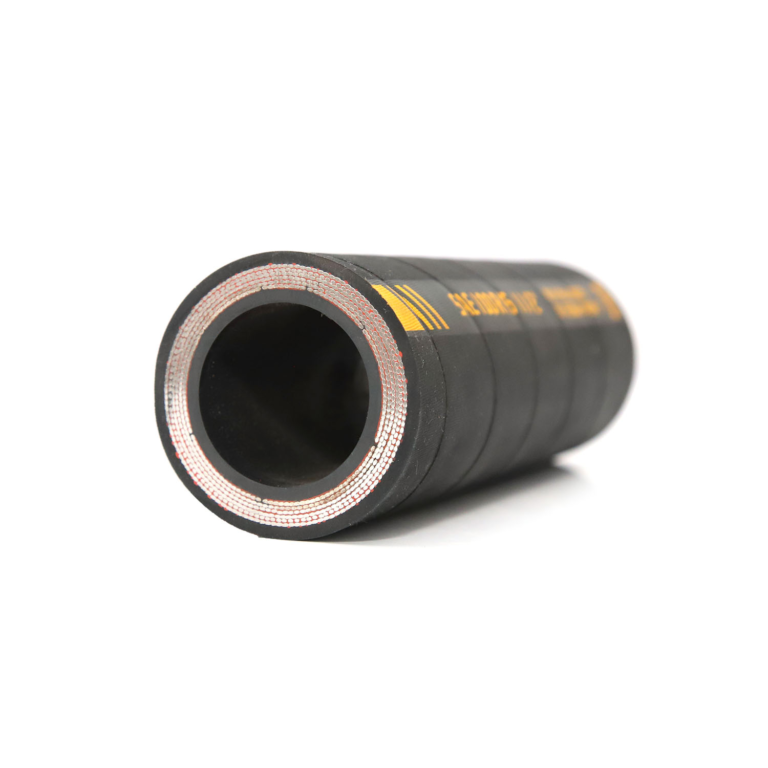

3. Prepare rubber hoses

Select the rubber hose to be tested, ensuring that its appearance has no obvious defects such as damage, cracks, deformation, etc.

Check the connection parts of the hose to ensure that the joints are secure and leak free.

二、 Installation and Connection

1. Install the hose

Install the rubber hose according to the actual usage method, ensuring that the bending radius and connection angle of the hose meet the requirements.

If necessary, fixtures or brackets can be used to secure the hose to prevent movement or shaking during testing.

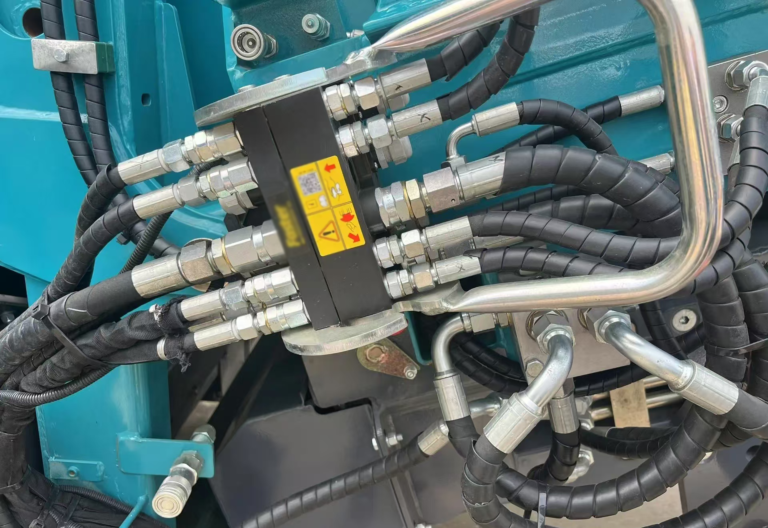

2. Connect the testing equipment

Connect the pressure testing equipment to the rubber hose. Usually, quick couplings, threaded connections, and other methods can be used for connection.

Ensure that the connection is well sealed and free from leaks. During the connection process, sealing materials such as sealant and tape can be used to assist in sealing.

三、 Conduct stress testing

1. Slowly increase the voltage

Start the pressure testing equipment and slowly increase the pressure. The boosting speed should be controlled within the specified range, and generally should not be too fast to avoid impact on the hose.

Observe the pressure indication and record the pressure value and time during the pressure rise process.

2. Maintain pressure

When the pressure reaches the specified test pressure, maintain the pressure for a period of time. The holding time should be determined according to the requirements of the testing standards, generally ranging from a few minutes to several tens of minutes.

During the period of maintaining pressure, closely observe the appearance changes of the rubber hose and whether there are any leaks. Leakage can be checked using methods such as visual observation and applying soapy water.

3. Slowly reduce pressure

After maintaining pressure, slowly reduce the pressure. The pressure reduction speed should also be controlled within the specified range to avoid negative pressure causing damage to the hose.

Record the pressure value and time during the depressurization process.

四、 Result determination and processing

1. Result judgment

According to the qualification criteria in the testing standards, determine the pressure test results of the rubber hose. If the hose has no leakage, rupture, obvious deformation or other phenomena during the testing process, and the pressure value is within the specified range, it is judged as qualified.

If the hose leaks, ruptures, deforms, or the pressure value exceeds the specified range, it is judged as unqualified.

2. Processing results

For qualified rubber hoses, they can continue to be used or undergo further processing.

For unqualified rubber hoses, they should be marked and isolated for storage, and should not be used again. Depending on the specific situation, unqualified hoses can be repaired, replaced, or scrapped.

五、 Test records and reports

1. Record test data

During the pressure testing process, detailed test data should be recorded, including testing time, pressure values, hose numbers, appearance changes, and other information.

Test records should be accurate, complete, and traceable for subsequent quality analysis and problem troubleshooting.

2. Write a test report

Write a stress test report based on the test records. The test report should include the test purpose, test method, test results, conclusion, and other contents.

The test report should be signed and confirmed by the testing personnel, and stamped with the official seal of the testing unit.

In short, the pressure test of rubber hoses needs to be strictly carried out according to the prescribed steps to ensure the accuracy and reliability of the test results. During the testing process, attention should be paid to safety to prevent accidents from occurring. If you have any questions or uncertainties about the stress testing process, you can consult professional technicians or relevant institutions.