Characteristics of resin hose

1..Chemical stability

Hoses made of resin materials have good corrosion resistance. They can play a certain role in blocking and tolerating chemicals of different pH values. For example, in chemical production, when transporting acidic or alkaline solutions, resin hoses will not be easily corroded, ensuring the safety and stability of fluid transmission.

It can resist the erosion of various organic solvents. In occasions involving the transportation of organic chemical reagents, it has a longer service life and higher reliability than ordinary rubber hoses.

2..Flexibility

The resin hose is soft and elastic. This allows it to adapt to various complex pipeline layouts during installation and use. In a small space, it can be easily bent and twisted without affecting the transmission of fluids, and will not break or break due to repeated bending.

Its flexibility is also reflected in its adaptation to pressure changes. When the fluid pressure fluctuates, the hose can buffer the pressure through its own elastic deformation and reduce damage to the connection parts and the pipe body itself.

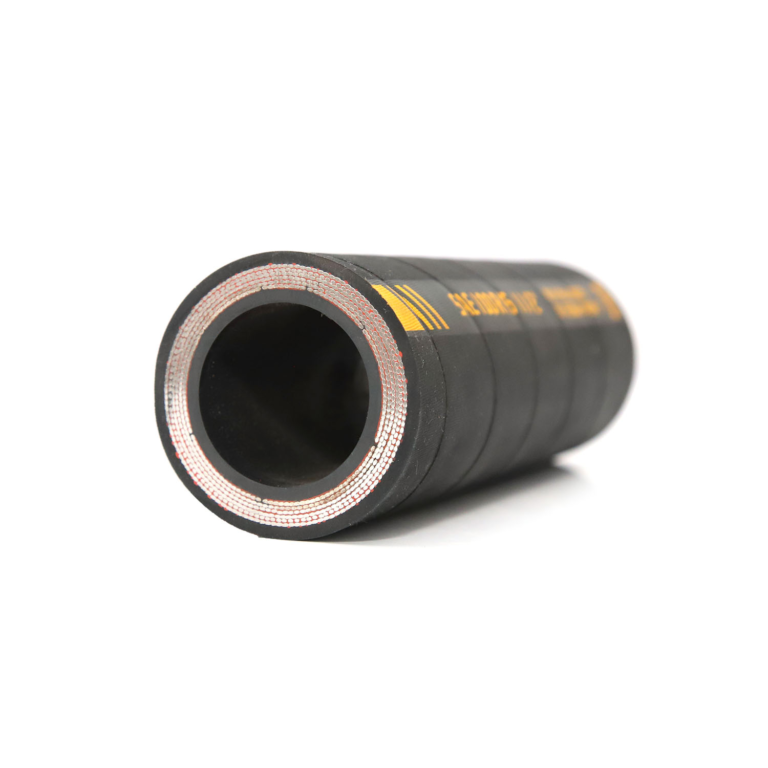

3..High strength

Although the resin hose is relatively soft, it has high strength. It can withstand certain internal and external pressures without breaking. In industrial applications, such as the resin hose used in high-pressure water cleaning equipment, it can remain intact under the impact of high-pressure water flow.

At the same time, it also has good resistance to wear and scratches. In some rough use environments, such as when transporting materials at construction sites, the surface of the resin hose is not easily worn, ensuring its performance and life.