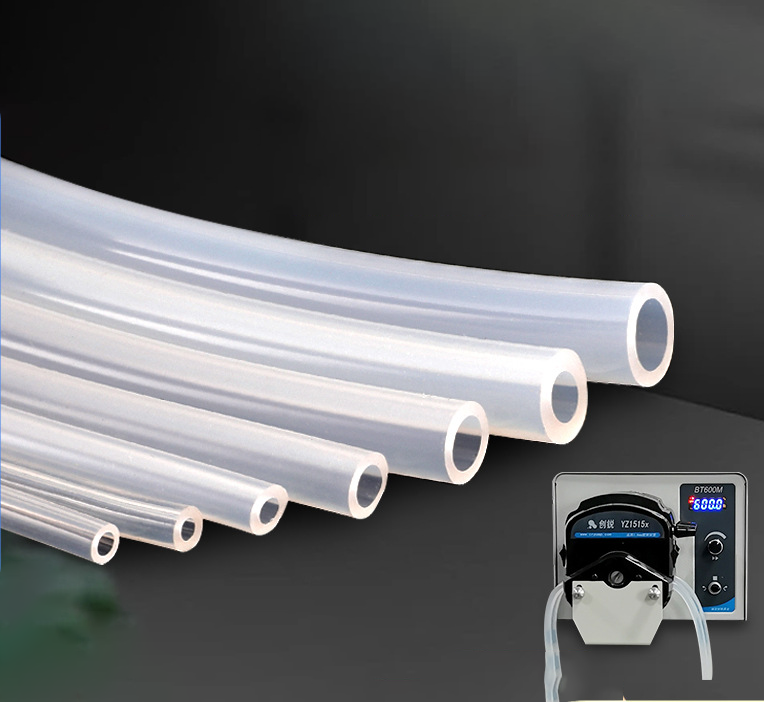

What are the storage conditions and shelf life of rubber products?

Rubber products may fail due to changes in their physical and chemical properties caused by various external environmental factors such as distortion, oxygen, ozone, light, heat sources, moisture, oil, or chemical solvents. Basic regulations have been made for the storage, cleaning, and maintenance of rubber seals in standards such as DIN7716, ISO2230, and DIN9088.

Temperature: 5-25 ℃ is an ideal storage temperature. Avoid contact with heat sources and sunlight. Seals removed from low-temperature storage should be placed in an environment of 20 ℃ before use. Humidity: The relative humidity of the warehouse should be less than 70% to avoid being too humid or too dry, and condensation should not occur. Lighting: Avoid sunlight and strong artificial light sources containing ultraviolet rays. UV resistant packaging bags can provide the best protection. Suggest painting the windows of the warehouse with red or orange paint or applying thin film. Radiation: Avoid damage to seals caused by ionizing radiation. Oxygen and ozone: Rubber materials should avoid exposure to circulating air. This can be achieved through packaging, wrapping, storage in airtight containers, or other suitable methods. Ozone is harmful to most elastomers, and the following equipment should be avoided in the warehouse: mercury vapor lamps, high-voltage electrical equipment, electric motors, etc. Deformation: Rubber parts should be placed in a free state as much as possible to avoid tension, compression, or other deformations. Contact with liquid or semi-solid materials: Do not come into contact with solvents, oils, fats, or other semi-solid materials. Contact with metal or non-metal materials: It is not allowed to come into contact with magnetic materials, cast iron, copper and its alloys, or materials that may damage rubber. PVC material cannot be used to package seals. Seals made of different materials cannot be mixed together. Cleaning: Seals can be cleaned with soap or water as needed. But water cannot come into contact with fiber-reinforced seals, rubber metal adhesive seals, and AU material seals. Disinfectants, organic solvents, and tools with sharp edges are not allowed to be used. The cleaned seal should be air dried at room temperature and should not be exposed to heat sources. The shelf life of seals is determined by the type of rubber material and storage conditions. Under the recommended storage conditions, the shelf life of each material seal is as follows: polyurethane, thermoplastic material 4 years nitrile rubber, hydrogenated nitrile rubber, chloroprene rubber 6 years ethylene propylene rubber 8 years fluororubber, silicone rubber, fluorosilicone rubber 10 years perfluororubber 20 years polytetrafluoroethylene indefinite. After exceeding the above period, the characteristics of the rubber parts should be checked before use, or they can still be used for a period of time.