Basic knowledge of commonly used soft rubber materials

Soft rubber material is a general term for soft materials with a soft and gentle touch. Soft rubber materials include rubber and plastic, such as rubber, silicone rubber, TPU, TPE, soft PVC, etc.

The main properties that soft rubber products focus on include hardness, elasticity, corrosion resistance, wear resistance, susceptibility to cracking, coloring performance, high (low) temperature resistance, cost, processing technology, etc. If used with daily necessities and baby products, it is also necessary to pay attention to factors such as whether the materials are harmful to humans, whether there is an unpleasant odor, and whether the hand feel is comfortable.

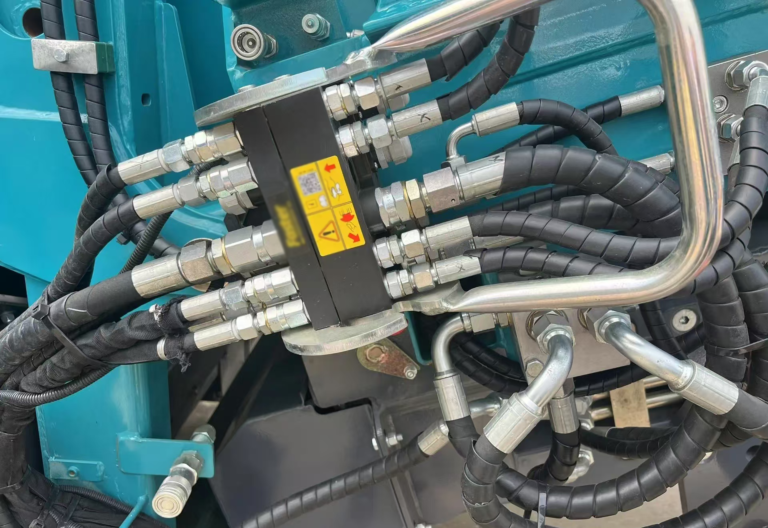

Soft rubber materials are widely used, and are commonly seen in our daily lives as follows

1. The main material of soft rubber covers in the medical industry is silicone,

2. Electronic products, phone cases, plugs, sealing rings, cushioning pads, etc,

3. Toys, dolls, baby products, etc.

4. Adult products

We have previously introduced the characteristics of PVC. Next, we will mainly introduce the characteristics of silicone, rubber, TPU, and TPE.

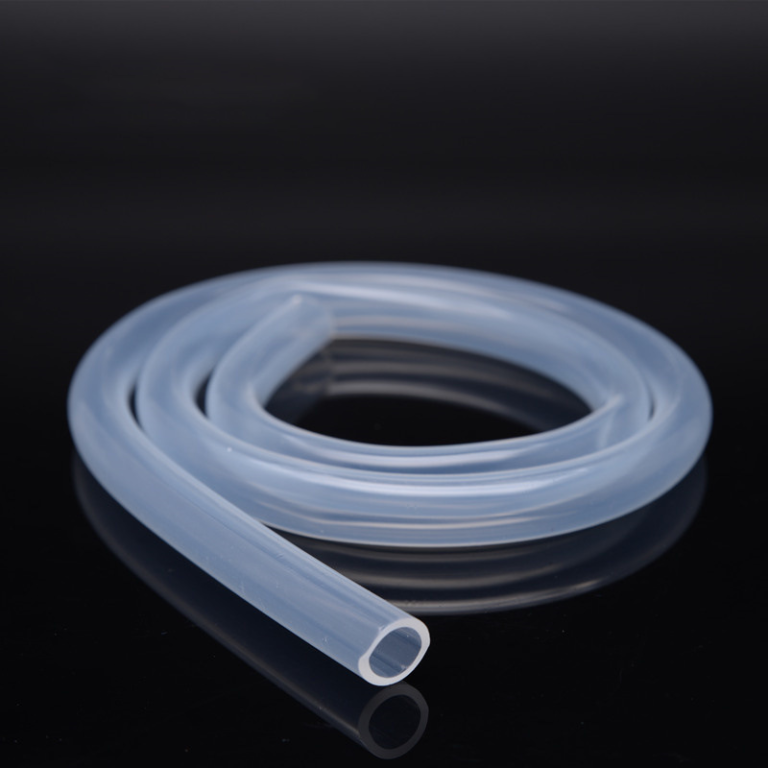

1. Introduction to Silicone

The main component of silicone is silicon dioxide, which is a thermosetting elastomer. According to its properties and composition, it can be divided into two categories: organic silicone and inorganic silicone. Inorganic silicone has high adsorption performance; Organic silicone is a type of organic silicon compound. Hardness can be adjusted and was first widely used in adult and food products.

2. Advantages of silicone

a、 Safe, non-toxic, odorless

b、 Chemical stability

c、 Good thermal stability

d、 High mechanical strength

e、 High adsorption performance, can be used as a desiccant

f、 Adjustable hardness

3. Disadvantages of silicone

a、 Poor mechanical properties such as tensile strength and tear resistance, as well as poor resistance to strong alkali and hydrofluoric acid

4. Application scope of silicone gel

Widely used in construction, electronics and electrical, textile, machinery, automotive, pharmaceutical and medical, chemical, metal and paint, adult products, infant and toddler products, etc.

1. TPE Introduction

TPE is a thermoplastic elastomer material. Thermoplastic means it can be recycled and reused, and can be injection molded. TPE products have excellent coloring properties, are environmentally friendly and non-toxic. It can be molded by secondary injection molding, coated and bonded with matrix materials such as PP, PE, PC, ABS, or molded separately.

2. Advantages of TPE

a、 Non toxic and safe,

b、 Wide range of hardness,

c、 It has excellent coloring properties, soft touch, weather resistance, fatigue resistance and temperature resistance, superior processing performance, no need for vulcanization, higher processing efficiency than rubber, and can be recycled to reduce costs. It can be molded by secondary injection molding, wrapped and bonded with matrix materials such as PP, PE, PC, PS, ABS, or molded separately.

3. Disadvantages of TPE

a. TPE’s heat resistance is not as good as rubber, and its physical properties decrease significantly with increasing temperature, thus limiting its applicability.

b、 Compression deformation, resilience, and durability are inferior to rubber, and the price is often higher than similar rubber.

4. TPE is used in various optical cables, cables, automotive sealing strips, steering wheels, bumpers, brake oil pipes, seat cushions, coatings, modified asphalt, plastic modification, bottle caps, straws, rubber bands, condoms, and for manufacturing manual and electric tool blood transfusion bags, syringes, infusion bags, gloves, etc.

1. TPU Introduction

The Chinese name is thermoplastic polyurethane elastomer. TPU is a polymer material formed by the reaction and polymerization of diisocyanate molecules such as diphenylmethane diisocyanate (MDI) or toluene diisocyanate (TDI) with high molecular weight polyols and low molecular weight polyols (chain extenders). There are various molding processes for TPU, including injection molding, blow molding, compression molding, extrusion molding, etc. Among them, injection molding is the most common.

2. Advantages of TPU

a、 Wide range of hardness

b、 High mechanical strength

c、 Outstanding cold resistance and good processing performance

e、 Good wear resistance, toughness, strong tear resistance, oil resistance, water resistance, and mold resistance

3. Disadvantages of TPU

a、 Poor weather resistance

b、 Poor compression resistance

c、 Poor hot water resistance

d、 Poor formability,

e、 Higher cost and less flexibility than silicone

4. TPU is commonly used in construction, electronics and electrical, textile, automotive, machinery, leather and papermaking, medicine and medical fields