What should I do if the diameter of the rubber joint pipe connection is different?

In the case of excessive pressure, in addition to choosing rubber joints, expansion joints can also be connected, but rubber joints have obvious advantages in terms of performance and installation. Some people may say that rubber joints are made of all rubber materials, while expansion joints are made of carbon steel materials. Compared to the installation environment, we have gained a detailed understanding of the usage and installation environment of rubber hose joints.

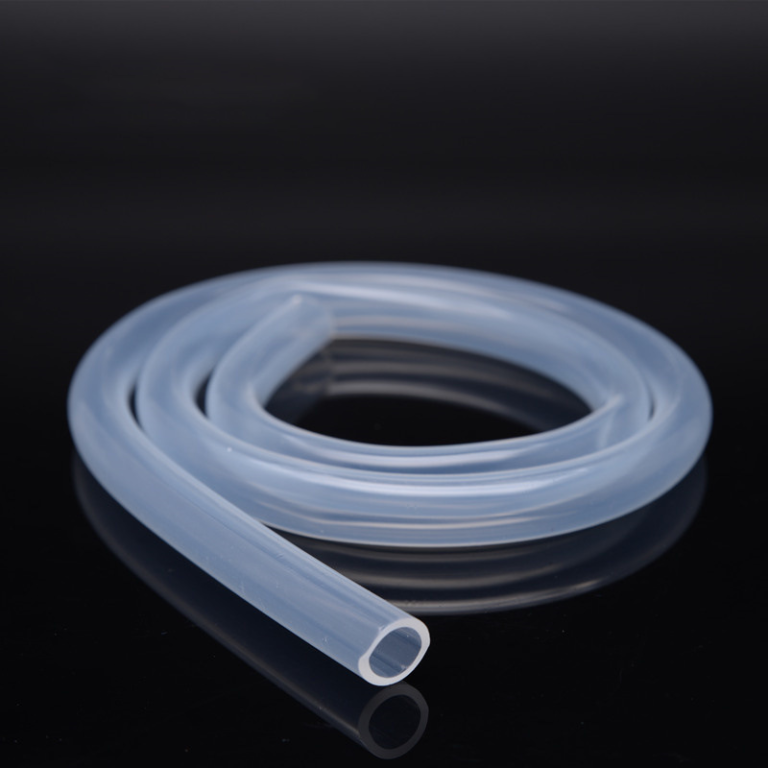

Rubber hoses are connectors required to connect pump and valve products. Why are rubber hose joints better than expansion joints? The working pressure of rubber hose joints refers to the pressure generated through pipelines, including fluids such as air, compressed air, water, seawater, hot water, oil, acid, alkali, etc. Most manufacturers are unable to produce high-pressure rubber joints. The explosive pressure of rubber joints refers to the potential for them to explode, tear, and damage under such pressure. Therefore, it is required that the pipeline pressure should not exceed the explosion pressure. How to choose the working pressure of rubber joints? This should be selected based on the pressure of the pump and pipeline. To cope with the working pressure of pipelines and equipment, it is not allowed to install low pressure rubber joints on high pressure pipelines, which may damage the pipelines and equipment. There will be clear markings on the packaging, and pressure markings on the main body of the rubber hose connector. In addition, we can see the thickness of the flange. If the flange is relatively thin, the working pressure of the rubber joint will decrease, otherwise the pressure will increase.