Working principle of crimping machine – crimping operation method and maintenance

1、 Working principle of pipe press machine

The oil pump is installed in the oil tank and immersed in hydraulic oil to achieve the design goal of scientific heat dissipation and noise reduction. The oil pump is driven by a motor to output hydraulic oil, which drives the plunger in the clamping cylinder to move, causing the mold seat to radially contract and achieve the extrusion of the rubber hose joint sleeve by the mold. When the shrinkage reaches the predetermined value of the micrometer, the squeezing automatically stops, the electromagnetic directional valve shifts backwards, the plunger in the oil cylinder moves in the opposite direction, the mold opens accordingly, and the clamping of the rubber hose is completed.

2、 Installation and commissioning of pipe press machine

Handling: The pipe press is suitable for forklift handling, and the bottom of the pipe press is subjected to force. It is strictly prohibited to invert the pipe press. It is strictly prohibited to lift the pressure pipe head, motor, and electrical box parts.

Installation: The pipe press should be placed horizontally on a stable foundation and grounded.

Oil injection: Open the oil tank cap and add 68 # anti-wear hydraulic oil to the oil tank to the 2/3 position of the oil level gauge.

Power on: Connect the power cord to the designated power source of the pressure tube machine, start the motor and observe the direction of rotation. The direction of rotation of the motor should be consistent with the direction marked on the motor. If the motor direction is not consistent with the marked direction, please swap the positions of two power lines.

Micrometer: used to adjust the size of the contraction of the compression hose. Press it counterclockwise by 1mm more and clockwise by 1mm less.

Pressure adjustment: The maximum pressure of the pipe press system is 31.5Mpa, which is adjusted by the overflow valve. The pressure is increased by clockwise adjustment and decreased by counterclockwise adjustment (it has been adjusted at the factory and can be adjusted by oneself if necessary).

Adjustment of mold opening speed: The speed of mold opening is controlled by a diversion valve. Clockwise adjustment increases the opening speed, counterclockwise adjustment slows down the opening speed. However, if the opening speed is too fast, it will increase the noise. The optimal value is not greater than 10Mpa (it has been adjusted at the factory and can be adjusted if necessary).

3、 Pressing operation

When using the pipe press machine for the first time, it should be unloaded and pressed 20-30 times, and all parts should be observed to be normal before use.

During winter use, the pipe press should be unloaded and pressed 20-30 times to increase the oil temperature.

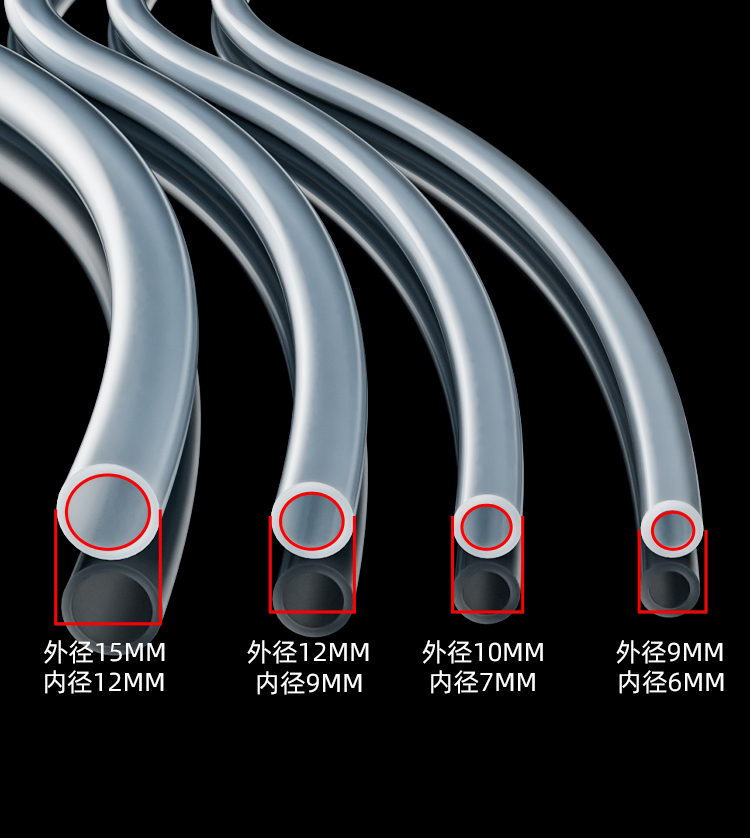

Press the open button, and after the mold seat is opened, select the corresponding mold according to the specifications of the clamped rubber hose and install it on the mold seat, and adjust the micrometer scale. Place the rubber hose with the fitting in the appropriate position inside the pressure tube head, so that the entire length can be compressed at once.

Press the crimping button to perform the crimping operation until the crimping machine head stops crimping and automatically opens the mold.

Take out the clamped rubber hose assembly and use a vernier caliper to check the outer diameter size of the clamped joint sleeve. If it does not match the parameter table, adjust the micrometer scale until the next rubber hose is clamped to meet the requirements.

4、 Pressure tube test example

Buckle the four layer steel wire hose with a diameter of 19mm (Italian Manuli4sp standard)

According to the hydraulic oil pipe crimping parameter table, the outer diameter of the outer sleeve of the four layer steel wire rubber hose joint with a diameter of 19mm was 37mm before crimping and 33.5mm after crimping. The inner diameter of the mold that should be selected is 33mm, corresponding to a micrometer scale of 3. Install the Ø 33mm mold on the mold seat, and rotate the micrometer scale to 3 places. Peel off the rubber hose and assemble it with the joint. After the crimping is completed, measure the outer diameter of the joint jacket to obtain the value of 33.5mm in the crimping parameter table, and the crimping is complete. If the outer diameter does not match after crimping, adjust the micrometer and crimp the next rubber hose. When crimping the hose joint: if the crimping size is too large, the rubber layer inside the hose will be crushed, causing oil leakage; The compression size is too small, causing oil leakage and detachment of the joint by hydraulic pressure. It is necessary to master the reasonable clamping degree, based on the shrinkage of the inner hole of the joint core. The compression of the national standard joint is 0.1~0.4mm less, and the compression of the ordinary joint is 0.1~2mm less. Due to different manufacturers of rubber hoses and joint sleeves, such as most rubber hose manufacturers in the north using GB standards, those in the south using 602 standards, and foreign SAE standards, the specific dimensions and materials of rubber hoses and joints may vary from factory to factory. Therefore, the data in the crimping parameter table is for reference only, and the specific crimping dimensions should be based on pressure experiments.

5、 Precautions for Pipe Pressing Machine

When crimping, try to place the joint at the center of the mold as much as possible, and do not press it on the hex nut.

2. Prevent tools and other foreign objects from entering the pressure tube head.

3. After each work is completed, the eight mold seats must be opened to the maximum extent, which can keep the spring in an open state, maintain the spring, and the oil cylinder in a pressure relief state to extend the life of the oil seal.

6、 Maintenance and upkeep of pipe press machine

When the hydraulic oil in the oil tank exceeds the time limit specified by the hydraulic oil manufacturer, it should be replaced or the oil level gauge should be visually inspected. If the hydraulic oil has oxidized and turned black, it must be replaced.

2. Regularly inject anti-wear lubricating oil into the moving surface of the mold seat.

3. During non pressure pipe machine working hours, please cover the dust cover to prevent debris from entering the mold seat.