When selecting industrial hoses, attention should be paid to the bending radius of the hose

The bending radius of a hose refers to the vertical distance from the centerline of the bent part to the outside of the bend during the bending process. It is an important parameter that needs to be considered in the design and use of hoses, directly affecting their performance, service life, and safety.

Firstly, we need to clarify the definition of bending radius. The bending radius refers to the minimum bending degree that a hose can achieve without damage or deformation on its inner side during bending. If the bending radius is too small, it may cause the internal structure of the hose to be compressed, deformed, or even damaged, thereby affecting its normal function.

Next, we will consider the main factors that affect the bending radius of the hose:

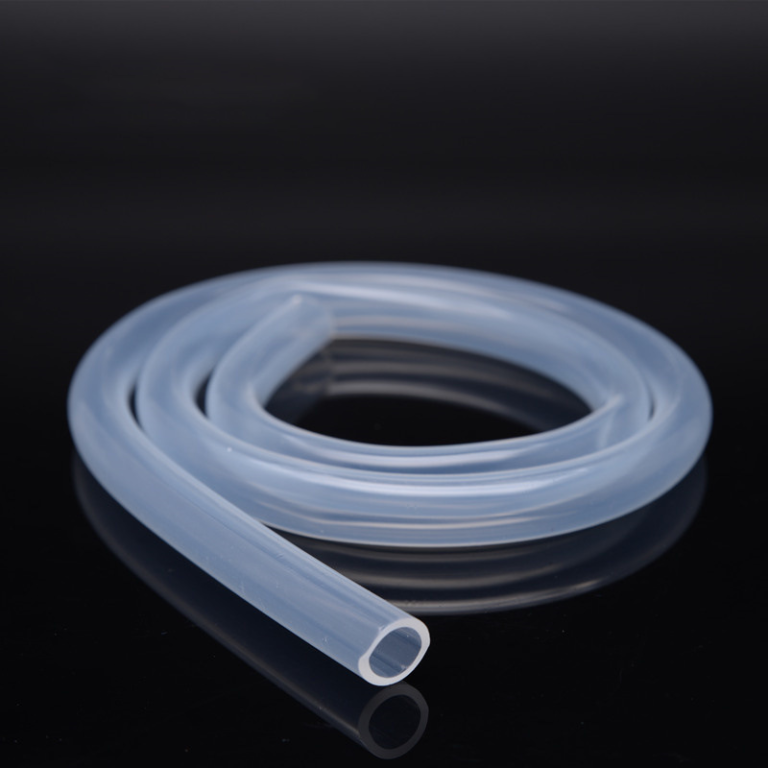

1. Material characteristics: Hoses made of different materials have different bending properties. For example, hoses made of rubber or certain plastic materials typically have good flexibility, allowing them to work with smaller bending radii. Metal hoses, on the other hand, often require a larger bending radius due to their harder material. Therefore, when selecting hoses, it is necessary to choose the appropriate material based on the actual working environment and bending requirements.

2. Hose wall thickness: The thickness of the hose wall also affects its bending radius. Thicker wall thickness means higher structural strength and better pressure resistance, but it may also increase the difficulty of bending and require a larger bending radius. On the contrary, although thinner walls are prone to bending, they may sacrifice some strength and durability.

3. Hose diameter: The larger the hose diameter, the larger the required bending radius. This is because a larger diameter means more material needs to be bent, increasing the difficulty of bending and potential damage risks.

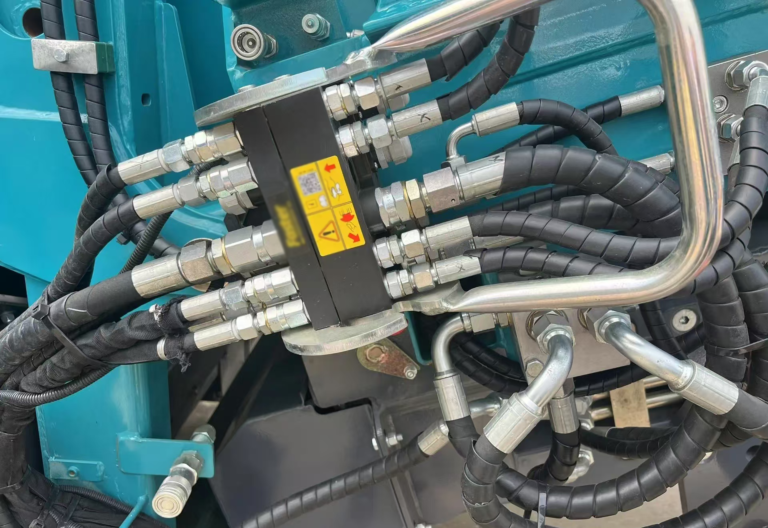

In addition, the specific application scenarios of the hose also need to be considered. For example, in situations where frequent bending or quick installation and disassembly are required, hoses with smaller bending radii and good flexibility should be selected. In environments that require significant external pressure or long-term stability, it may be necessary to choose hoses with larger bending radii and higher structural strength.

Finally, it is essential to refer to industry standards and regulations. These standards are usually based on a large amount of experimental data and practical application experience, which can provide strong guidance for selecting the appropriate bending radius. For example, the international standard ISO 6945 specifies the basic requirements for the bending radius of hoses, which means that the curvature radius of the bent part of the hose should not be less than 4 times the outer diameter of the hose.