What are the advantages and disadvantages of rubber hoses

Rubber hoses, as a common pipeline material, have many advantages and some limitations. The following are the main advantages and disadvantages of rubber hoses:

1. Advantages:

(1) Corrosion resistance: Rubber hoses typically have good corrosion resistance to various chemicals and can be used to transport a variety of liquids, including acids, alkalis, oils, and solvents.

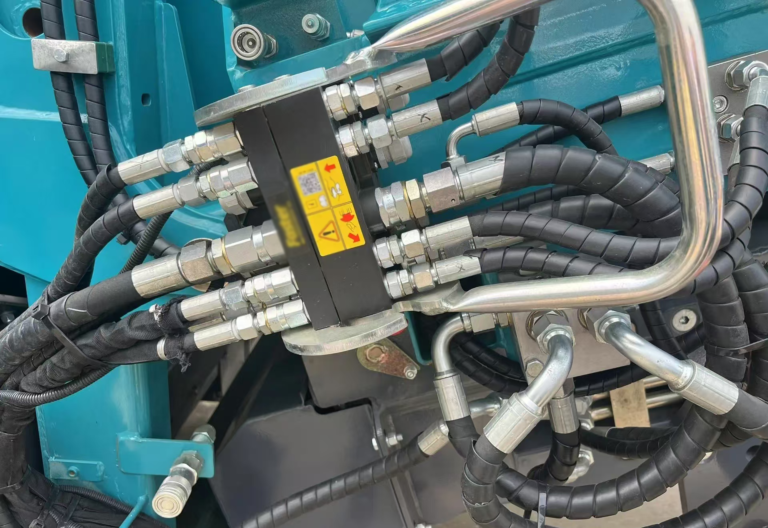

(2) Elasticity and flexibility: Rubber hoses are very flexible, easy to bend and install, making them suitable for a variety of applications, including in small spaces.

(3) Vibration absorption and damping performance: Rubber materials can reduce impact and vibration, minimize the impact load on mechanical equipment, and extend equipment life.

(4) Wear resistance: Rubber hoses have a certain degree of wear resistance and can resist wear and grinding to a certain extent.

(5) Insulation: Rubber is an excellent electrical insulation material that can be used for electrical insulation applications.

(6) Sealing performance: Rubber hoses usually have good sealing performance and can be used to prevent liquid or gas leakage.

(7) Vibration absorption and sound insulation performance: Rubber hoses can reduce the propagation of noise and vibration, making them suitable for applications that require noise and vibration reduction.

2. Disadvantages:

(1) Limited high-temperature resistance: Rubber hoses may harden, age, or decompose in high-temperature environments, making them unsuitable for high-temperature applications.

(2) Vulnerable to UV damage from sunlight: Rubber hoses exposed to sunlight may be damaged by UV radiation, leading to aging and cracking.

(3) Limited oil resistance: Some types of rubber have limited oil resistance to petroleum products and may be damaged by long-term exposure to petroleum or grease.

(4) Maintenance requirements: Rubber hoses may require regular maintenance and replacement, especially in high-pressure, high-temperature, or corrosive environments.

(5) Restricted tensile strength: Compared to metal pipes, rubber hoses have relatively lower tensile strength and are not suitable for applications that can withstand high tension.

In summary, rubber hoses have their unique advantages and limitations in various applications. When choosing rubber hoses, it is necessary to comprehensively consider the application environment, material characteristics, and performance requirements to ensure the selection of the most suitable pipeline material.