Advantages and guidance for judging the crimping machine

一、 Judging the pros and cons

1. See: It is by visually observing whether the hydraulic accessories and electrical components selected for the crimping machine and pipe pressing machine are branded products or produced by legitimate manufacturers; Is the circuit configuration organized; Is the pipeline design of the gas station reasonable; Is there any oil leakage at the connection point. If the above has passed the visual inspection, the next step of testing can be carried out.

2. Listen: Turn on the device and start it. Check if the sound of the device running is normal. If there is abnormal noise, it is often caused by the poor coaxiality of the motor and oil pump installation, another possibility is due to the unreasonable selection of oil pump displacement and pipe diameter, and another possibility is due to the poor quality of the selected motor or oil pump.

3. Measurement: Finally, measure the main parameters of the equipment

(1.) Keep the device in an empty running state and touch each module block with your hand. There should be no shaking sensation, otherwise it will be considered as an unqualified product.

(2.) Install the equipment onto the mold, press a sample joint, and measure the joint with a caliper or micrometer. The roundness and taper should be within 0.1mm, which is considered excellent.

(3.) The hardness of the mold seat and mold is also the key to whether the equipment can be used normally in the future. Customers can request the manufacturer to use a desktop or portable hardness tester to test the mold base or mold. When the hardness of the mold seat is lower than Rockwell HRC60 and the hardness of the mold is lower than Rockwell HRC50, it will affect the crimping quality of the hose.

(4.) Finally, check the eight fold division of the equipment mold base and the flatness of the mold. Good equipment will specifically control and adjust these two parameters, while some low-quality equipment does not control the above two parameters.

二.Guidance

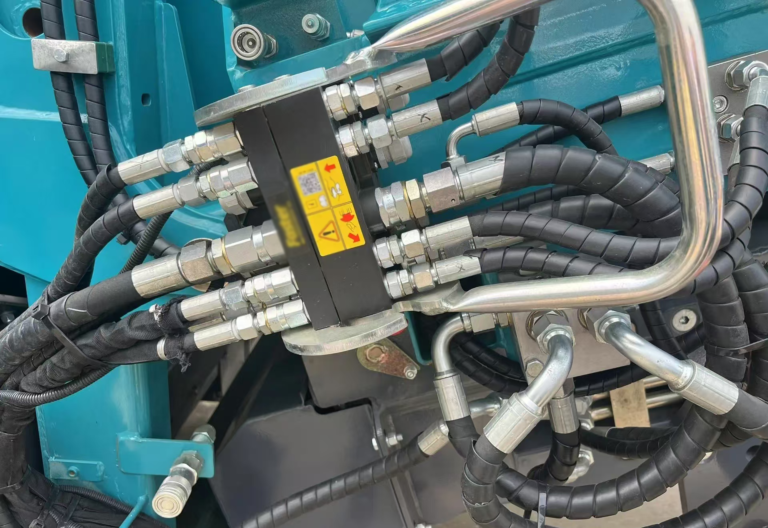

1. Adopting the principle of dual hydraulic circuit operation, the piston’s advance and retreat, as well as the mold’s opening and contraction movements, all rely on the power generated by the hydraulic power source. It not only moves smoothly and returns quickly, but also does not experience the phenomenon of spring return, which makes the mold unable to open and lock. Moreover, the design of the oil cylinder locking system is front and rear through, making it easy to clamp various special-shaped elbows.

2. The hydraulic system consists of a motor, oil pump, solenoid valve, pressure regulating valve, and hydraulic valve, forming a dual hydraulic oil circuit with forward and backward movement. In addition, a quick release valve oil circuit is added to the dual hydraulic oil circuit to achieve faster return, with adjustable speed, reduced noise, and system pressure.

3. In terms of electrical control systems, the control circuit is suitable for PLC circuits, which are easy to maintain, convenient to repair, and easy to replace.

4. The crimping mold and mold base adopt a zero cumulative error processing technology to ensure that the crimping lines of the product are evenly spaced and free of large and small head phenomena after crimping.

5. In order to ensure the permanent mechanical accuracy and service life of the clamping machine, not only high-quality alloy steel materials are selected for the locking mechanism components, but also a unique heat treatment process is adopted. So the longer service life of the press machine is closely related to the rationality of material selection, heat treatment, mechanical processing technology, and structure.

6. For double column crimping machines and C-type crimping machines, due to the inconvenience of setting dead positioning, numerical control must be used to control the crimping size, such as products from Fenbao and UNIFLEX manufacturers.

7. Deduction standard

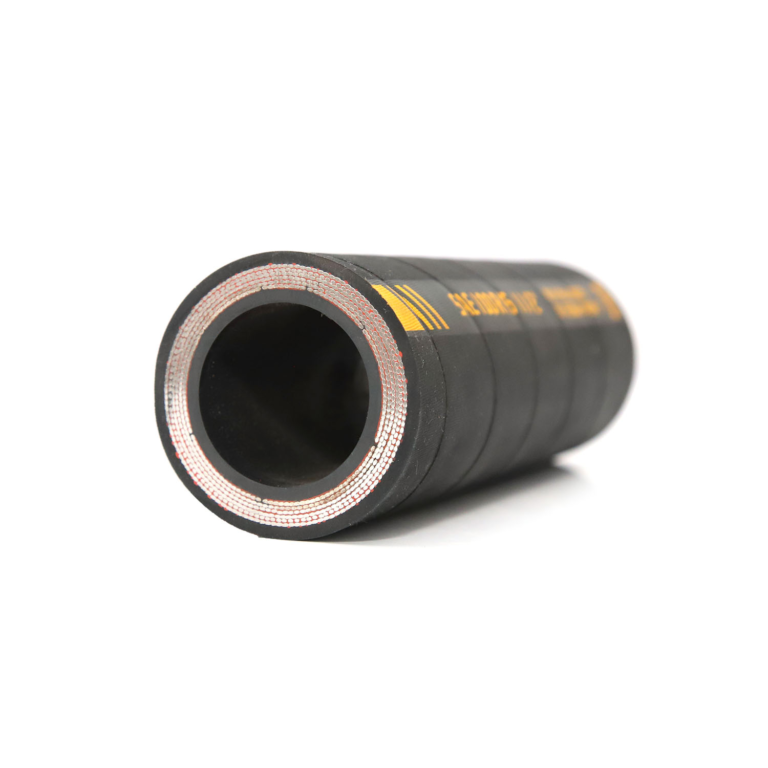

Theoretical requirement: Do not remove the head or damage the rubber inside the hose

To avoid detachment, the pressure should be high, and to avoid damaging the inner rubber, the pressure should be low. To solve this contradiction, the first step is to choose a non tapered (0 taper) pipe press to ensure that the data at both ends of the hydraulic metal joint is consistent, avoiding errors. (Note: If the compression force at the front end of the metal joint is too strong, it will damage the joint. If the compression force at the back end of the metal joint is too strong, it will fracture the rubber inside the hose, leading to oil leakage, etc.).