What is industrial grade rubber hose?

characteristic

Compared to civilian hoses, industrial operating environments are more complex and harsh, and equipment requirements for conveying pipes are also more stringent. Therefore, industrial hoses have strict specifications and standards in terms of design, material selection, production, transportation, and even final storage.

The size range of industrial hoses is wider, the pressure and temperature range is wider, and the chemical resistance is higher.

application

The application field of industrial hose covers various industrial production, manufacturing and circulation fields, and is widely used in petroleum, chemical industry, ships, docks, tank cars, agriculture, food, beverage, medicine and other industries, as well as cold and hot water, steam, ventilation, cooling, fire fighting, hydraulic pressure, and media such as gas, water, fog, muddy water, sand, iron particles and so on.

workmanship:

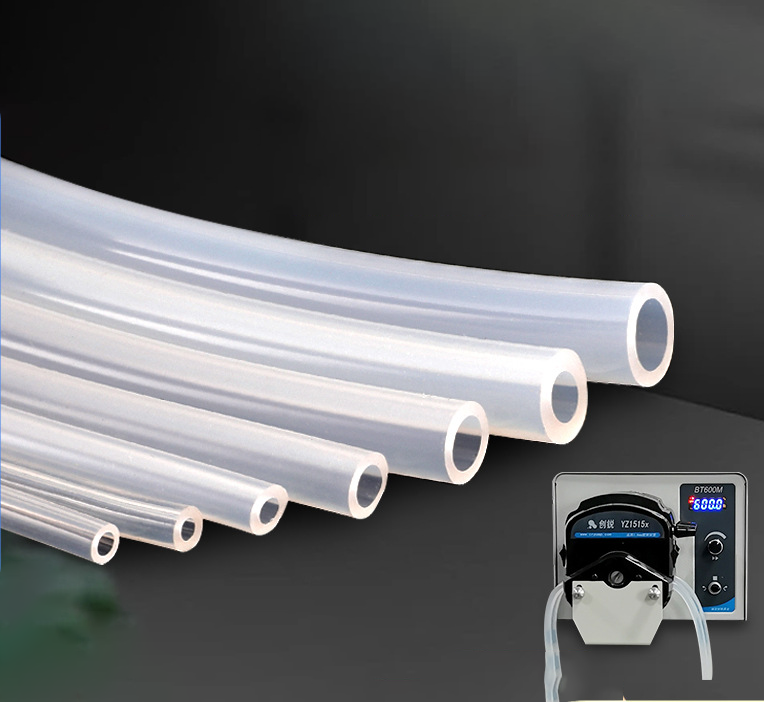

Industrial grade rubber hoses, regardless of whether the medium is water, gas, oil, chemicals, or others, usually consist of an inner rubber, an outer rubber, and an intermediate layer. The middle layer is usually composed of woven components, which play a role in strengthening the strength of the hose.

In addition, steel wires are commonly embedded between the inner and outer adhesives, which are suitable for vacuum negative pressure operations.

There is also a conductive wire that is suitable for work environments that prohibit the generation of sparks, such as fuel.

classification:

In order to adapt to the physical and chemical conditions of various industries, industrial hoses usually have very strict standards for the chemical raw materials and processes of internal and external colloids. According to the classification of working conditions, common ones include:

Water supply hose. Used for irrigation, horticulture, construction, fire protection, equipment and tank truck cleaning, agricultural fertilizers, manure, industrial wastewater drainage, etc. The internal rubber materials are mostly PVC and EPDM.

Hot water and steam hoses. Used for cooling water in refrigeration equipment, engine hot and cold water, food processing, especially for hot water and saturated steam in dairy factories. The internal rubber material is mostly EPDM.

Beverage and food hoses. Used for non lipid applications such as milk, carbonated beverages, orange juice, beer, animal and vegetable oils, drinking water, etc. The internal rubber material is mostly NR or synthetic rubber. Usually, food grade FDA, DVGWA, KTW, or CE certification is required.

Air hose. Used in compressors, pneumatic devices, mining, construction, and other fields. The internal adhesive materials are mostly NBR, PVC composite, PU, and SBR. There are usually strict requirements for the applicable pressure.

Welding hoses. Used for gas welding, cutting, and other applications. The inner rubber material is mostly NBR or synthetic rubber, while the outer rubber is usually colored red, blue, yellow, etc. to indicate the specific gas.

Ventilation hose. Used for emissions of hot air, dust, smoke, chemical gases, etc. The internal adhesive is mostly made of thermoplastic materials and PVC. Usually, the pipe body has a retractable design.

Material suction hose. Used for fluid transportation of solid particles such as gas, mist, powder, particles, fibers, gravel, cement, fertilizers, coal dust, quicksand, concrete, gypsum, etc. The internal adhesive materials are mostly NR, NBR, SBR, and PU. Usually, the outer rubber has high wear resistance.

Oil hose. Used in fuel, diesel, kerosene, petroleum and other fields. The internal adhesive materials are mostly NBR, PVC composite, and SBR. Usually, there is a conductive steel wire between the inner and outer adhesives to prevent sparks.

Chemical hoses. Used for acidic and chemical solutions, etc. The internal rubber material is mostly EPDM. Usually, this type requires customized materials and design solutions.