Internal and external factors affecting the aging of rubber hoses

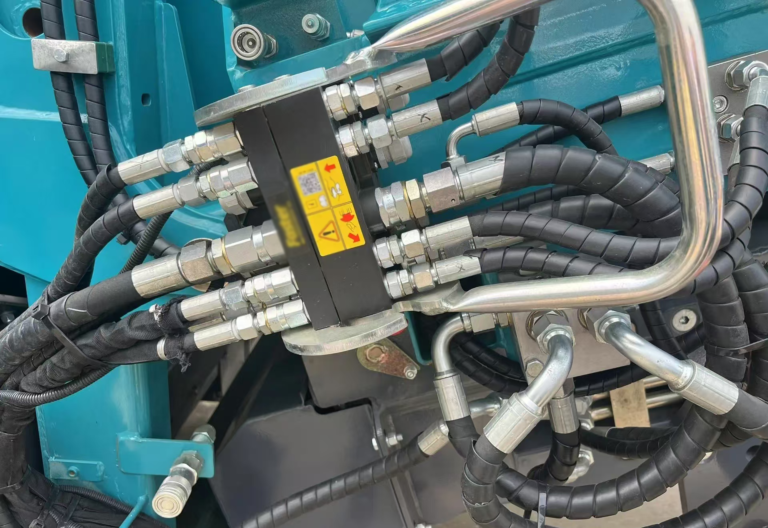

Rubber hose is a flexible pipe made of rubber material, which has good bendability and elasticity, and can withstand certain pressure and tension. Rubber hoses are widely used in fields such as petroleum, chemical, machinery, metallurgy, and ships for transporting liquids, gases, and solid materials, especially playing an important role in situations that require flexible arrangement and installation.

Rubber hoses will undergo changes in their properties due to various factors during use, resulting in a gradual decrease in the performance of rubber and its products over time, until they are damaged and lose their usefulness. This process is called rubber aging. Aging of rubber hoses can cause economic losses, and one way to reduce these losses is to prolong the life of the hose by slowing down aging. To slow down aging, it is necessary to first understand the factors that cause hose aging.

1. Oxidation reaction is one of the important causes of rubber aging, and oxygen will react with certain substances inside the rubber tube, causing changes in rubber properties.

2. Increasing the temperature will accelerate the diffusion rate of nutrients and the reaction rate of oxidation reaction, accelerating the aging of rubber. On the other hand, when the temperature reaches the corresponding level, the rubber itself will undergo thermal cracking and other reactions, which will affect the performance of the rubber.

3. Light also has energy, and the shorter the light wave, the greater the energy. Among them, ultraviolet radiation is a high-energy light that can have a destructive effect on rubber. Rubber generates free radicals due to the absorption of light energy, triggering and accelerating the oxidation chain reaction. On the other hand, light also plays a role in heating.

When rubber is exposed to moist air or soaked in water, water-soluble substances in the rubber will be extracted and dissolved by water, especially in the case of water immersion and atmospheric exposure, which will accelerate the damage of the rubber.

When rubber is repeatedly acted upon, its molecular chains may break, and accumulating small amounts can cause cracking or even breakage of the rubber hose.