What is the function of the cloth hose?

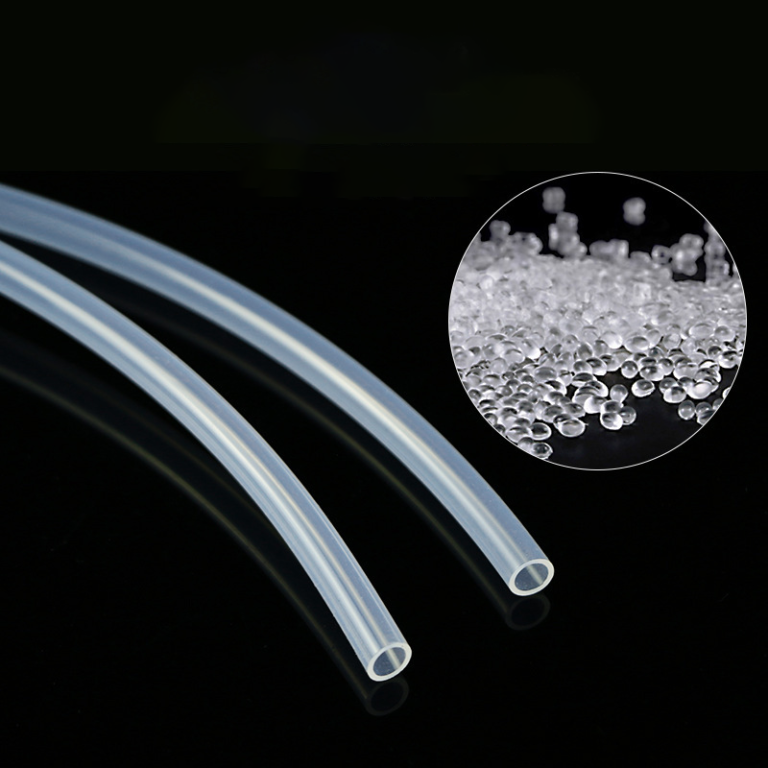

Cloth hose, also known as fabric hose, is mainly composed of three parts:

1. Inner rubber layer: This part is the part of the clamped rubber hose that directly contacts the conveying medium, so it requires the use of rubber materials with excellent oil and heat resistance properties. Common inner rubber layer materials include natural rubber, butyl rubber, chloroprene rubber, etc.

2. Multi layer woven or cord winding layer: This part is the main reinforcement layer of the laminated rubber hose, used to improve the pressure resistance and tensile resistance of the hose. Jiebu is a type of textile, commonly made of materials such as cotton cloth, polyester cloth, fiberglass cloth, etc. This layer can effectively prevent the hose from breaking or being damaged under high pressure or high-frequency vibration.

3. Outer rubber layer: This is the outer protective structure of the laminated rubber hose, mainly used to prevent damage to the internal structure of the hose from the external environment. The outer adhesive layer material is usually the same or similar to the inner adhesive layer, but may require stronger wear and aging resistance.

Characteristics of Gabu hose:

1.The characteristics of cloth clamped rubber hoses include small outer diameter tolerance, excellent oil and heat resistance, lightweight, soft and durable pipe body. The small burst pressure of its rubber hose is usually four times the working pressure.

2. According to the different medium resistance properties of the adhesive layer, laminated rubber hoses can be divided into various types, such as water pipes, air pipes, acid and alkali pipes, heat-resistant oil pipes, etc. These rubber hoses are widely used in fields such as industrial and agricultural machinery and equipment, for conveying various liquid viscous fluids and powdery solids and other material media.

3. Laminated rubber hoses are also widely used in industries such as chemical, petroleum, pharmaceutical, and food, such as conveying saturated steam, high-temperature liquids, corrosive media, etc. Its excellent corrosion resistance, high temperature resistance, and flexibility make laminated rubber hoses an indispensable conveying equipment in these industries.

In order to extend the service life of the cloth hose, regular maintenance and upkeep are necessary. Here are some suggestions:

*Avoid excessive bending or twisting of the hose to prevent damage to its internal structure.

*Regularly inspect the appearance and connection parts of the hose to ensure that it is not damaged or leaking.

*Before and after use, clean the dirt and residue inside and outside the hose.

*Avoid exposing the hose to sunlight, high temperatures, or chemicals to accelerate its aging process.