Characteristics of high-pressure oil pipes and hydraulic hoses

Characteristics of high-pressure hoses:

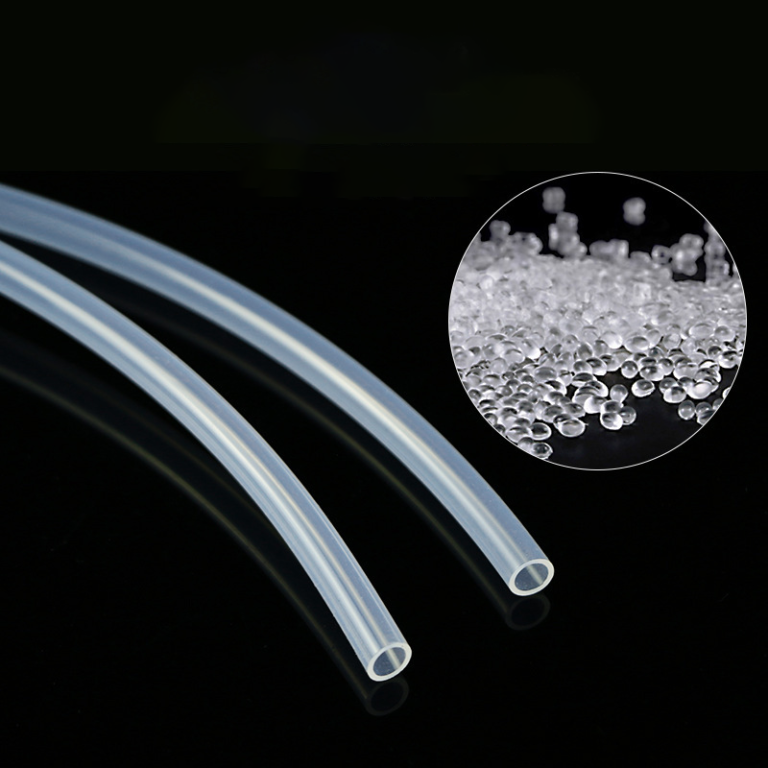

There are many types of high-pressure hoses, and the classification methods are also different. Some are classified by purpose, some by raw materials, and some by buttons. The following characteristics are the basis for classifying high-pressure rubber hoses; The structure and processing technology of high-pressure rubber hoses, the inner diameter of plastic hoses, working pressure values, the use and function of working materials, working environment, working temperature, and business scale. High pressure hoses are divided into steel fiber welding seals, rigid welding seals, steel argon arc welding seals, and core seals. Plastic hoses are divided into three types based on the agreed working pressure: bottom pressure, high pressure, and high pressure. Bottom pressure plastic hoses are usually single-sided and sleeve type, without lifting waveforms. Develop the compressive strength of high-pressure hoses when working under pressure using the following methods

Add plastic mesh bags on the second or third layer, and add spiral unloading lines and waveform thickness in the pipe groove to obtain high-pressure rubber hoses that work smoothly under high pressure and high pressure. According to their usage, high-pressure rubber hoses can be divided into three types: plastic hoses used for transporting corrosive, non corrosive liquids, and steam. The key power circuit adopts high-voltage rubber hoses to shield the transmission lines and prevent them from being damaged by mechanical equipment and coming into contact with liquids

High pressure rubber hoses are used as mobile pipeline compensators to eliminate temperature and equipment deformations in various mechanical equipment hydraulic press management systems. Use high-pressure hoses with plastic mesh bags under high pressure. High pressure hoses used for working under long-term vibration standards have a wide excitation frequency and limited bounce frequency. The high-pressure hose must undergo long-term impact testing at operating frequency. Judging its working ability based on impact compressive strength and vibration resistance

The high-pressure hose adopts the standards of frequent bumps, anti bumps, and narrow oscillation frequency band. This high-pressure hose must undergo long-term bump tests in a narrow vibration frequency band to understand the hazards of repeated bumps and transportation impacts on its working ability. Improved the structure of the high-pressure hose and the tight connection between the joint and the plastic mesh bag, greatly reducing the welding time, improving reliability, and increasing the service life by 1-2 times. This advantage has led to the widespread application of high-pressure hoses.

Advantages of hydraulic hoses:

1. Excellent pressure resistance: Rubber hoses can withstand high pressure and large flow of liquid or gas media, and their pressure resistance is very excellent.

2. Good wear resistance: Rubber hoses can withstand strong friction and wear, and have good wear resistance.

3. Good corrosion resistance: Rubber hoses can withstand corrosion and erosion from various media, and have good corrosion resistance.

4. Good flexibility: Rubber hoses have good flexibility and can adapt to complex working environments and working conditions.

5. The rubber hose is made of special synthetic rubber, which has excellent oil resistance, heat resistance, and aging resistance.

6. The pipe body is tightly combined, soft to use, and has minimal deformation under pressure.

7. Rubber hoses have excellent resistance to bending and fatigue.

8. The rubber hose has high pressure bearing capacity and superior pulse performance