Temperature resistance of industrial hoses made of different materials

In modern industrial production, hoses are widely used as pipelines for transporting fluids and gases. According to different usage environments and requirements, the material of industrial hoses also varies. Among them, temperature resistance is an important performance indicator of industrial hoses, which directly affects the service life and effectiveness of the hoses.

The following is a detailed explanation of the temperature resistance of several common industrial hoses:

1. Rubber hose:

Natural rubber: The temperature resistance range is usually between -50 ℃ and 80 ℃. Natural rubber may undergo deformation and aging at high temperatures, therefore it is not suitable for high-temperature environments.

Styrene butadiene rubber: The maximum temperature resistance is generally around 120 ℃. Beyond this temperature, its mechanical properties and chemical stability will significantly decrease.

EPDM rubber: has excellent weather resistance and ozone resistance. Its working temperature range is usually -45 ℃ to 150 ℃, but the specific temperature resistance also depends on its formula and manufacturing process.

2. Plastic hoses:

Polyvinyl chloride (PVC): The temperature resistance range is generally between -15 ℃ and 60 ℃. PVC is prone to softening at high temperatures, making it unsuitable for long-term use in high-temperature environments.

Polyethylene (PE): Common PE pipes have a temperature resistance range of approximately -40 ℃ to 60 ℃. Some specially formulated PE pipes may have higher temperature resistance.

Polypropylene (PP): PP material usually has a high temperature resistance range and can be used within the range of -20 ℃ to 100 ℃. However, long-term high-temperature use may lead to a decrease in its performance.

3. Metal hoses:

Stainless steel: One of the main materials for metal hoses, with a wide operating temperature range of -196 ° C to 600 ° C. This enables metal hoses to perform excellently in various extreme temperature environments.

Aluminum and copper: Although aluminum and copper also have some temperature resistance, they are usually not as widely used as stainless steel. They are more commonly used in specific scenarios, such as those that require lightweight materials.

4. Nylon hose:

Nylon generally has a maximum high temperature resistance of 120 ℃. Excessive temperature can cause softening, expansion, and even melting. But some specially formulated nylon tubes can withstand higher temperatures, reaching around 150 ℃.

5.Polytetrafluoroethylene (PTFE) hoses:

Under normal usage conditions, the temperature range that can be tolerated is -196 ℃ to+260 ℃. Some PTFE materials with special formulas can even withstand high temperatures above 300 ℃. PTFE hoses are often used in high-temperature and highly corrosive environments due to their excellent resistance to high temperatures and chemical corrosion.

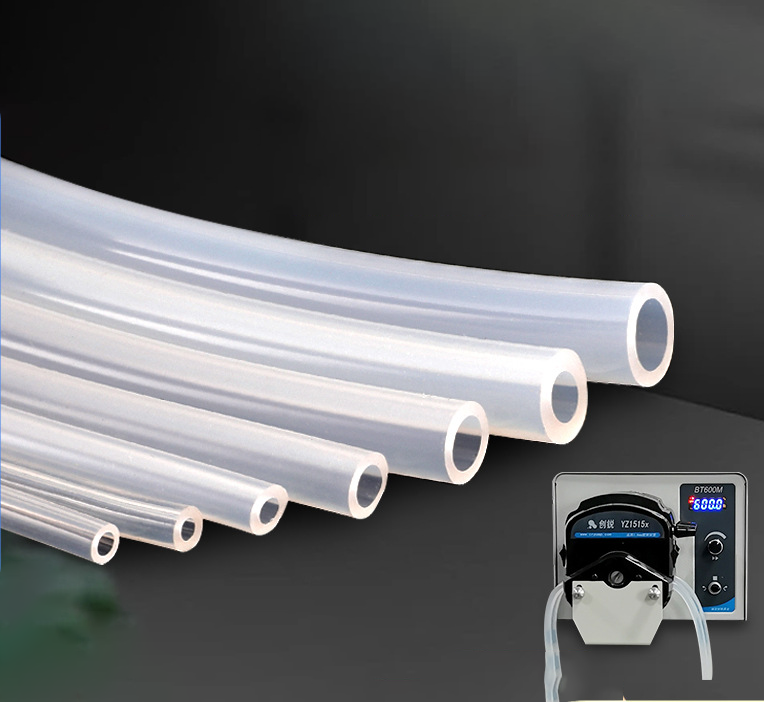

6. Silicone hose:

Silicone has excellent high temperature resistance, typically able to withstand temperatures up to 260 ℃ and maintain elasticity at temperatures as low as -50 ℃. Silicone hoses are non-toxic and odorless, so they are often used in fields such as food and medical care.