Sandblasting hose: the key link in industrial sandblasting

In the field of industrial manufacturing and surface treatment, sandblasting hose is an indispensable but often overlooked important tool. It is like a tough lifeline, connecting the sandblasting equipment and the spray gun, carrying the high-speed flow of sand particles, and playing a vital role in shaping the perfect surface of the workpiece.

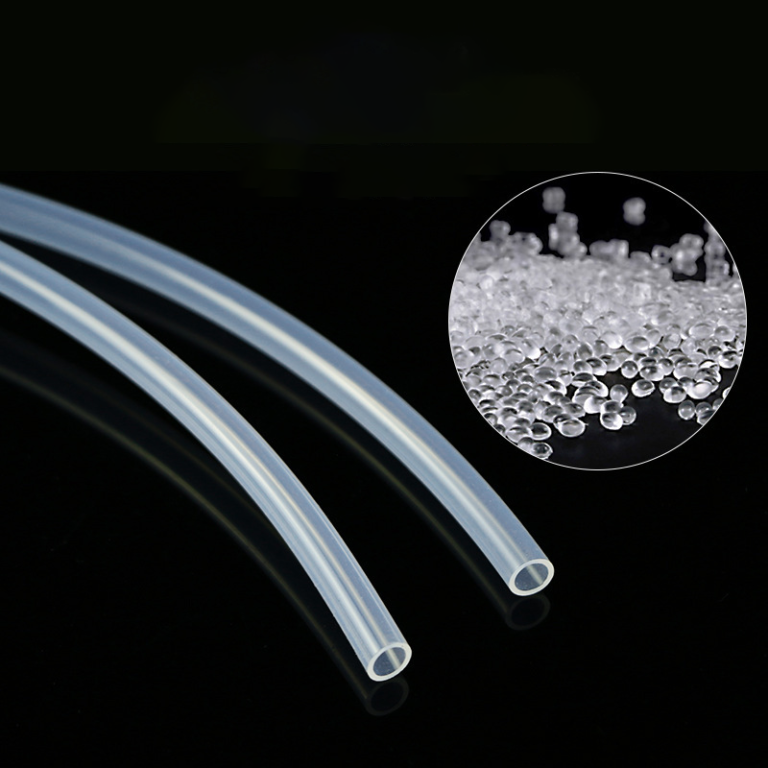

The structural design of the sandblasting hose is ingenious. It usually consists of three parts: inner rubber layer, reinforcement layer and outer rubber layer. The inner rubber layer is the part that directly contacts the sandblasting material, and it needs to have a high degree of wear resistance and corrosion resistance. This is because during the sandblasting process, the high-speed flowing sand particles will continuously impact the inner rubber layer. If the wear resistance is insufficient, the inner rubber layer will be worn out quickly, causing the hose to leak or rupture. At the same time, since the sandblasting material may have different chemical properties, such as acidic or alkaline, corrosion resistance has become another key characteristic of the inner rubber layer. This special inner rubber layer, like a loyal guard, silently guards the stable operation of the inside of the hose.

The reinforcement layer is the “skeleton” of the sandblasting hose. It is generally woven from high-strength fiber materials or steel wires to provide the hose with the necessary strength and pressure resistance. In the sandblasting operation, the sand particles have considerable energy under the push of high-pressure air, which will exert strong pressure on the hose. At this time, the reinforcement layer is like a solid fortress, resisting these pressures and preventing the hose from deforming or breaking under high pressure. The steel wire braided reinforcement layer performs particularly well in withstanding high pressure. It can keep the hose in a stable shape and good performance under extreme pressure conditions, just like putting on an indestructible armor for the hose.

The outer rubber layer is the “outer coat” of the sandblasting hose, which protects the reinforcement layer and the overall appearance. The outer rubber layer needs to have good weather resistance and aging resistance, because sandblasting operations are often carried out in various complex environments and may be affected by environmental factors such as direct sunlight, high temperature, and humidity. A high-quality outer rubber layer can maintain its flexibility and physical properties for a long time, ensuring that the hose can be used normally in harsh environments, just like a well-fitting and durable protective clothing, protecting the hose from erosion by the external environment.

The performance parameters of the sandblasting hose are important criteria for measuring its quality. The first is the inner and outer diameters of the hose. The right size is crucial to ensure sandblasting efficiency. If the inner diameter is too small, the sand flow will be poor and the sandblasting effect will be affected; if the inner diameter is too large, the sand speed may be reduced, and the ideal surface treatment quality cannot be achieved. The outer diameter needs to consider the connection matching with the sandblasting equipment and the spray gun to ensure that the connection is tight and stable. The second is the working pressure of the hose, which is directly related to the safety and reliability of the hose during the sandblasting process. A hose with insufficient working pressure is prone to rupture in a high-pressure sandblasting environment, causing safety accidents, while excessive working pressure requirements may increase unnecessary costs. In addition, the bending radius of the hose is also a key parameter. In actual sandblasting operations, the hose needs to bend and stretch according to the conditions of the workplace. If the bending radius is unreasonable, the internal structure of the hose will be damaged and its service life will be reduced.

In different industrial scenarios, sandblasting hoses have shown extraordinary adaptability. In the field of shipbuilding, the huge hull surface needs to be rust-removed and pre-treated, and the sandblasting hose can easily cope with long-distance, high-intensity sandblasting operations. It flexibly extends to every corner of the hull with the operation of the sandblasting worker, accurately spraying sand particles onto the rusty surface, laying a good foundation for subsequent coating processes. In the automotive manufacturing industry, for the surface treatment of some precision parts, sandblasting hoses need to have higher precision and stability. It can spray tiny sand particles evenly onto the surface of parts, remove burrs, improve surface roughness, and ensure the performance and appearance quality of parts after assembly. In the construction industry, stone carving and surface decoration are also inseparable from sandblasting hoses. It can accurately control the spray direction and strength of sand particles according to the requirements of designers, creating exquisite patterns and textures on hard stones.

However, sandblasting hoses also need careful maintenance during use. After each use, the sand particles and impurities remaining inside the hose should be cleaned in time to avoid them causing wear and tear on the internal structure of the hose. At the same time, the appearance of the hose should be checked regularly for damage, cracks, etc., especially at the connection parts and places with frequent bends. If problems are found, the damaged part or the entire hose should be replaced in time to prevent safety accidents. When storing, the sandblasting hose should be placed in a dry and cool place to avoid damage caused by direct sunlight and humid environment, and it should be carefully cared for like a precious cultural relic.

Sandblasting hose, the “behind-the-scenes hero” in this industrial field, provides solid support for modern industrial manufacturing and surface treatment industries with its unique structure, excellent performance and wide adaptability. It builds an invisible bridge between sand particles and workpieces, turning roughness into fineness and defects into perfection, driving industrial production towards higher quality.